By Russell Magnaghi

Beyond fur trading, mining, logging, and fishing, Upper Peninsula economic development proceeded along homespun lines. From the colonial era forward, local industries emerged despite the challenges of isolation, difficulties in transportation, uncertain weather, and fluctuating demand.

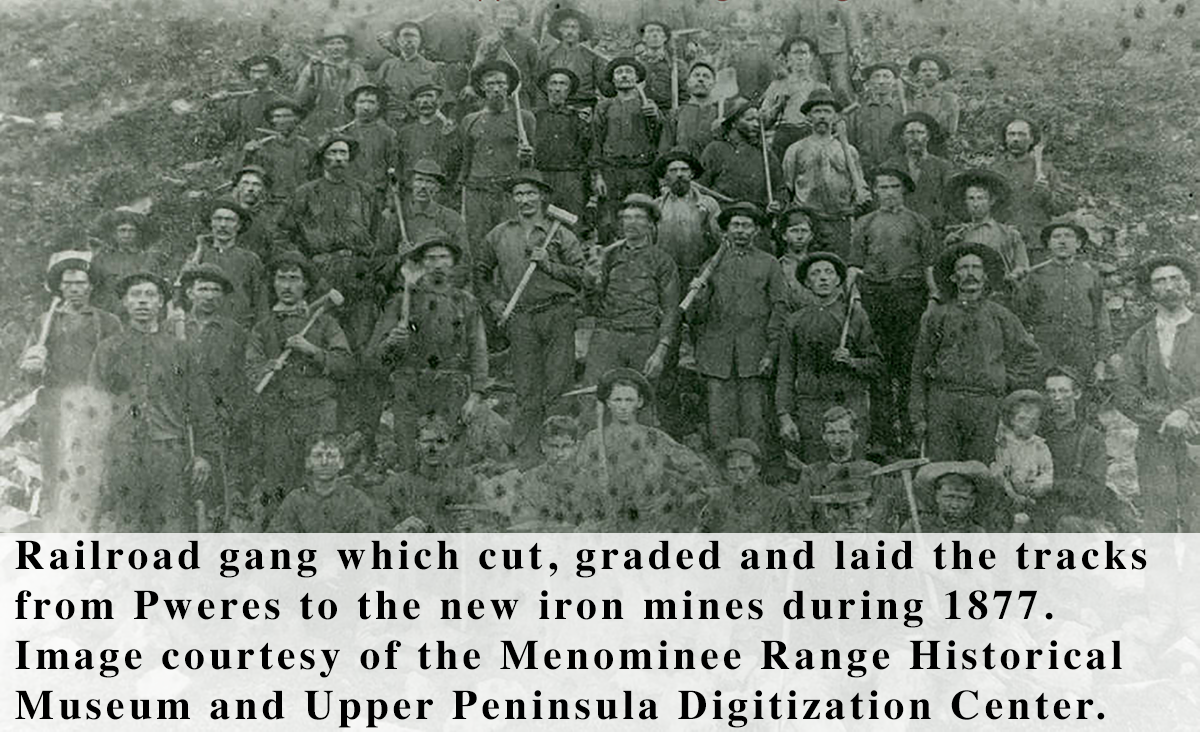

The mining frontier opened the UP. The basic industry in the western Upper Peninsula was mining: copper and iron. Numerous mines operated in the Copper Country - Keweenaw, Houghton, Ontonagon counties. Three iron ranges: Marquette, Menominee and Gogebic saw dozens of iron mines develop. Across the region the timber industry dominated the scene producing millions of feet of timber to construct American cities and support the mining industry.

The mining frontier opened the UP. The basic industry in the western Upper Peninsula was mining: copper and iron. Numerous mines operated in the Copper Country - Keweenaw, Houghton, Ontonagon counties. Three iron ranges: Marquette, Menominee and Gogebic saw dozens of iron mines develop. Across the region the timber industry dominated the scene producing millions of feet of timber to construct American cities and support the mining industry.

The fishing industry also dominated the economy since its Native American origins. In the early days it centered in the eastern Upper Peninsula and along the Lake Michigan shore from Mackinac to Menominee. Tons of fish were used locally or shipped away from the UP. Overfishing reduced the supply and by the 1960s fishing shifted from commercial to sports fishing.

One of the earliest industries was charcoal making which was used to smelt iron, especially at Fayette on the Garden Peninsula. Chemical plants, a natural corollary to smelting, emerged at Newberry and Marquette, while in the 1920s Henry Ford produced nationally recognized Kingsford Charcoal in Iron Mountain. Charcoal production continued well into the twentieth century.

Another early industry was boat building, especially in the eastern Upper Peninsula. Boats were needed for fishing and the industry developed to meet the demand. The major boat builder today is Marinette Marine, established in 1942 on the south bank of the Menominee River. The company has constructed more than 1,300 vessels, primarily commercial. Marinette had been awarded contracts to produce U.S. Navy vessels, mostly for auxiliary boats. In 2005 it launched the icebreaker Mackinaw that keeps the shipping lanes open around the U.P.

Some industries rose ancillary to the dominant industries - mining, logging, fishing. The mines needed  equipment, dynamite and massive timbers for reinforcing tunnels and shafts. The loggers and millers also depended on machinists and repair services.

equipment, dynamite and massive timbers for reinforcing tunnels and shafts. The loggers and millers also depended on machinists and repair services.

With the opening of the Marquette Iron Range many proprietors decided to develop forges or furnaces to process iron ore, removing the waste and shipping out pig iron. As a result numerous furnaces were developed in the 1850s and 1860s - Northern Iron Company, Collins Iron Company - to highlight a couple. However, experience showed them that it was less expensive to ship the iron ore out and the furnaces shut down.

In the Copper Country copper had to be processed depending on its form. Calumet and Hecla opened its stamp mill at Lake Linden and the Detroit & Lake Superior Copper Company operated a smelter at Hancock producing copper ingots to the value of $6 million in 1871. Across the Portage Lake in Houghton new development was undertaken in 1872-1873 when entrepreneurs established the Houghton County Copper, Iron & Tin Manufacturing Company. It was a rolling mill for the manufacture of sheet copper and copper bottoms.

Another important development was the creation of foundries and machine shops to manufacture machinery and repair and maintain mining equipment. By the mid-1860s there were foundries in Houghton and Marquette servicing the needs of the mines. At Marquette in 1872 the Iron Bay Foundry was opened and produced steam engines and boilers, mining and mill machinery and castings.”

The Lake Shore Engine Works of Marquette (today Lake Shore Systems, Inc., Kingsford, Michigan) had its origins going back to 1858 with the creation of the Lake Superior Foundry Company by Charles Harvey to produce mining and other machinery. It went through a number of owners and was incorporated in 1900. Located in the heart of the mining district it provided the lightest to the heaviest engines, drills and drilling machinery, steel mine and industrial cars, structural iron and steel work. Not only did the company serve the mines of the U.P. but those of the Far West, Mexico, Canada and India.

The Lake Shore Engine Works of Marquette (today Lake Shore Systems, Inc., Kingsford, Michigan) had its origins going back to 1858 with the creation of the Lake Superior Foundry Company by Charles Harvey to produce mining and other machinery. It went through a number of owners and was incorporated in 1900. Located in the heart of the mining district it provided the lightest to the heaviest engines, drills and drilling machinery, steel mine and industrial cars, structural iron and steel work. Not only did the company serve the mines of the U.P. but those of the Far West, Mexico, Canada and India.

A related chemical industry developed from the early iron furnaces at various locations across the peninsula. Charcoal furnaces at Negaunee, Marquette, Manistique, Newberry, and Gladstone belonged to Cleveland-Cliffs Iron Company, Pioneer Iron Company, and the Lake Superior Iron & Chemical Company. These plants not only produced pig iron, but charcoal; wood alcohol, acetone, and acetate used as solvents and a feedstock for the manufacture of other chemicals.

Dynamite, nitroglycerin, safety fuses and other explosives were in constant demand, with mines using at least 500,000 pounds monthly during the heyday of mining. The earliest explosive company opened in 1862 as it was safer to make the explosives locally. Eventually, there were plants operated by Pluto, Du Pont, Atlas, Aetna, Hercules and Iveco located across the mining area of the UP. Today the Dyno Nobel plant at National Mine continues this tradition.

Paper mills concentrated in Munising, Manistique, Escanaba and Ontonagon were an important component of the timber industry. These companies produced everything from tissues to uncoated paper as well. The Verso Corporation, a leading North American producer of coated paper used for media and marketing applications, operates the Escanaba Paper Company and the Quinnesec Mill. These plants employ over 900 people producing 800,000 tons of quality paper annually.

Besides paper production other timber industries sprang up around the U.P., producing everything from woodware to railroad ties, telephone poles to matchsticks and more. Escanaba became the center for transportation and wood products. It was home to the division headquarters for the Chicago & North Western Railway with s tie-treating plant and ore dock in the vicinity employing 750 men. The Escanaba Manufacturing Company was the largest wooden butter dish, pie plate, and clothespin factory in the world. The National Pole Factory was located here as well. The Bird’s Eye Veneer Company established in 1903 was a major producer of maple veneer which was used on the Queen Mary and in the Rockefeller Center Building in New York City, in the palaces of several Indian rajahs, and in cocktail bars and show windows.

The food and drink industry developed. Brewing goes back to 1850 when the first commercial brewery was  opened by Nikolaus Voelker and Joseph Clemens in Sault Ste. Marie. Breweries opened throughout the U.P. and flourished until state Prohibition in 1918. After Prohibition a few breweries were revived but it was not until the recent rise of craft breweries in the 1990s and 2000s that some seventeen breweries opened. Bakeries opened by Scandinavians and Italians in every community. The Carpenter-Cook Company in Menominee began in 1891 and became the major wholesale food distributor for the region. The company refined and canned locally grown vegetables, ran a pickle factory, roasted and sold coffee and operated the Michigan Candy Company. When it closed in 1976 its annual income was $45 million. The Vollwerth sausage company in Hancock is the last of many that operated in the region over the years. On Mackinac Island the fudge business is an industry using tons of sugar and known for its fabulous income during the summer months.

opened by Nikolaus Voelker and Joseph Clemens in Sault Ste. Marie. Breweries opened throughout the U.P. and flourished until state Prohibition in 1918. After Prohibition a few breweries were revived but it was not until the recent rise of craft breweries in the 1990s and 2000s that some seventeen breweries opened. Bakeries opened by Scandinavians and Italians in every community. The Carpenter-Cook Company in Menominee began in 1891 and became the major wholesale food distributor for the region. The company refined and canned locally grown vegetables, ran a pickle factory, roasted and sold coffee and operated the Michigan Candy Company. When it closed in 1976 its annual income was $45 million. The Vollwerth sausage company in Hancock is the last of many that operated in the region over the years. On Mackinac Island the fudge business is an industry using tons of sugar and known for its fabulous income during the summer months.

Menominee had been one of the major sawmill centers in the world but with the decline of the timber industry in the first decade of the 20th century, the city turned to manufacturing. The Lloyd Manufacturing Company’s wicker furniture plant became a mainstay of Menominee’s economic base. Also produced here was the Dudly Bug a gas powdered cycle-car, a popular two seater with an ash-wood frame. The Menominee Truck Company operated for several years. The Tideman family was involved with the Menominee Electrical and Mechanical Company since the 1890s and produced telephones, telegraph equipment, electric fans, bells and many other items. There was also a shoe manufacturing factory. In 1931 Menominee labeled itself “Cross Roads of Commerce,” a title shared with no rival in the U.P.

Sault Ste. Marie was the other industrial center in the Upper Peninsula. In the 1890s Francs H. Clergue created a hydroelectric powerhouse. The plant provided power for the Union Carbide Company which manufactured calcium carbide, the basis of acetylene gas used in welding. The Northwestern Leather Company, one of the largest such plants in America and produced high quality leather. The Soo Woolen Mill was the only mill of its kind operating in the U.P.

In the 21st century industry continues to grow. Gladstone, north of Escanaba, home to several businesses, including Marble Arms. In 1892 Webster L. Marble successfully established the Marble Safety Axe Company. It remains in operation as Marble Arms, an important member of the firearms and shooting sports industry. The timber industry continues to operate but well below its former levels of production. Wood-related industries -- flooring, log homes, construction, veneer, plywood and logging equipment -- also do well. Other industries have developed, as well, precision surgical equipment, plastics, injection molding, electronics, foundries, copper chemicals, steel and metal equipment, parts and machinery, helicopters and furniture to name a few. Small food manufacturers have built a small but flourishing industry. A much modified apparel industry has returned to the Upper Peninsula aided by the tourist trade. Yooper woolen Stormy Kromer hats are produced in Ironwood at the rate of 50,000 annually. Stores and gift shops sell tee-shirts and sweats carrying “U.P.” and “906” themes produced locally. Numerous local authors have developed a cottage industry based on self-publishing.